The Beer Making and Testing Process

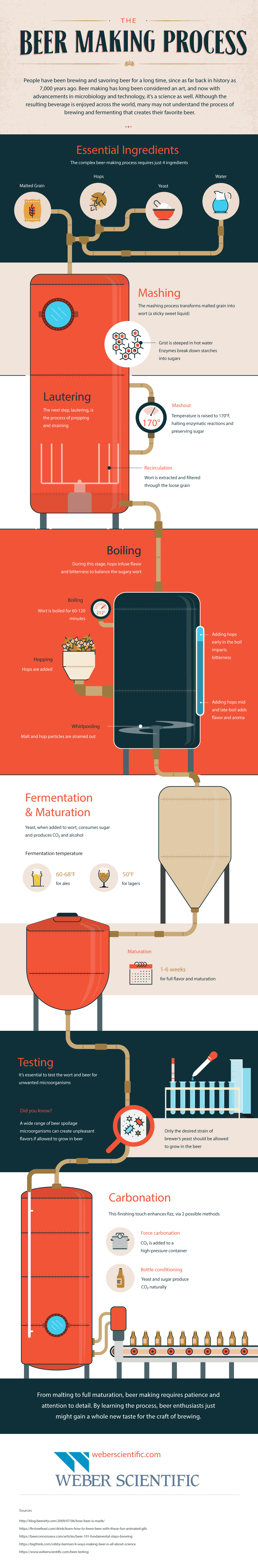

People have been brewing and enjoying beer for more than 7,000 years. Beer making is a unique combination of art and science, with modern microbiology and technology advances constantly improving the process.

Beer Making Ingredients

To make beer, four ingredients are required:

- Malted Grain

- Hops

- Yeast

- Water

The Beer Making Process

The beginning of the beer making process is composed of mashing, lautering, boiling, fermentation, and maturation. Where the mashing process transforms malted grain into wort, loitering preps and strains the wort in preparation for boiling. Boiling is where flavor comes in, as the hops infuse flavor and bitterness to balance the sugary nature of the wort. Finally, yeast is added to the wort, producing CO2 and alcohol. After 1-6 weeks of maturation, beer makers can expect full flavor to be present.

Beer Testing

But maturation is not where the beer making process ends. Beer testing is a vital element of the brewing and distribution of beer. It is essential to test the wort and beer for unwanted microorganisms. Once tested, the beer is ready for carbonation - the finishing touch that enhances fizz.

To see more, view Weber Scientific’s new infographic below: